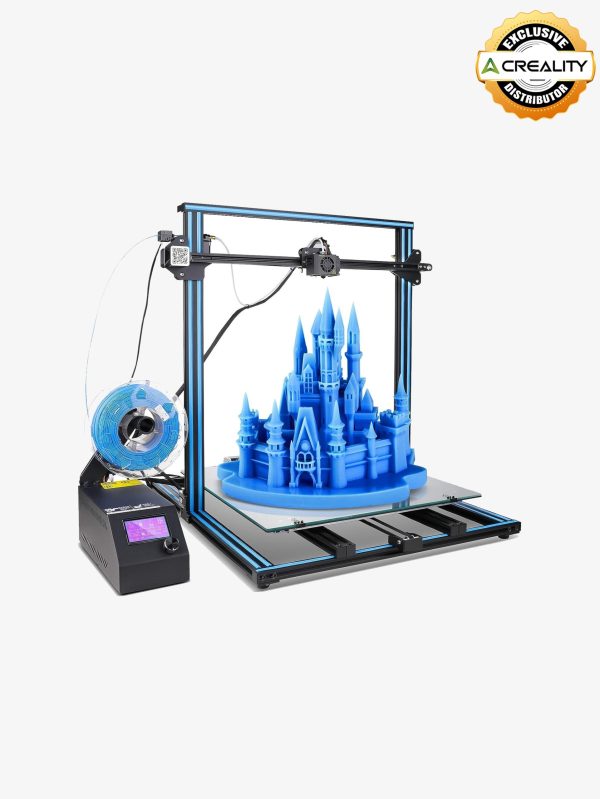

Description

Specifications

GENERAL SPECS

- Technology: FDM

- Year: 2018

- Assembly: Semi-assembled

- Mechanical arrangement: Cartesian-XZ-head

MATERIALS

- Filameter diameter: 1.75 mm

- 3rd party filaments: Yes

- Compatible materials: PLA, ABS, TPU, composite filaments

3D PRINTING PROPERTIES

- Accuracy: +/-100 Micron

- Layer height: 100 – 400 Microns

- Feeder system: Bowden

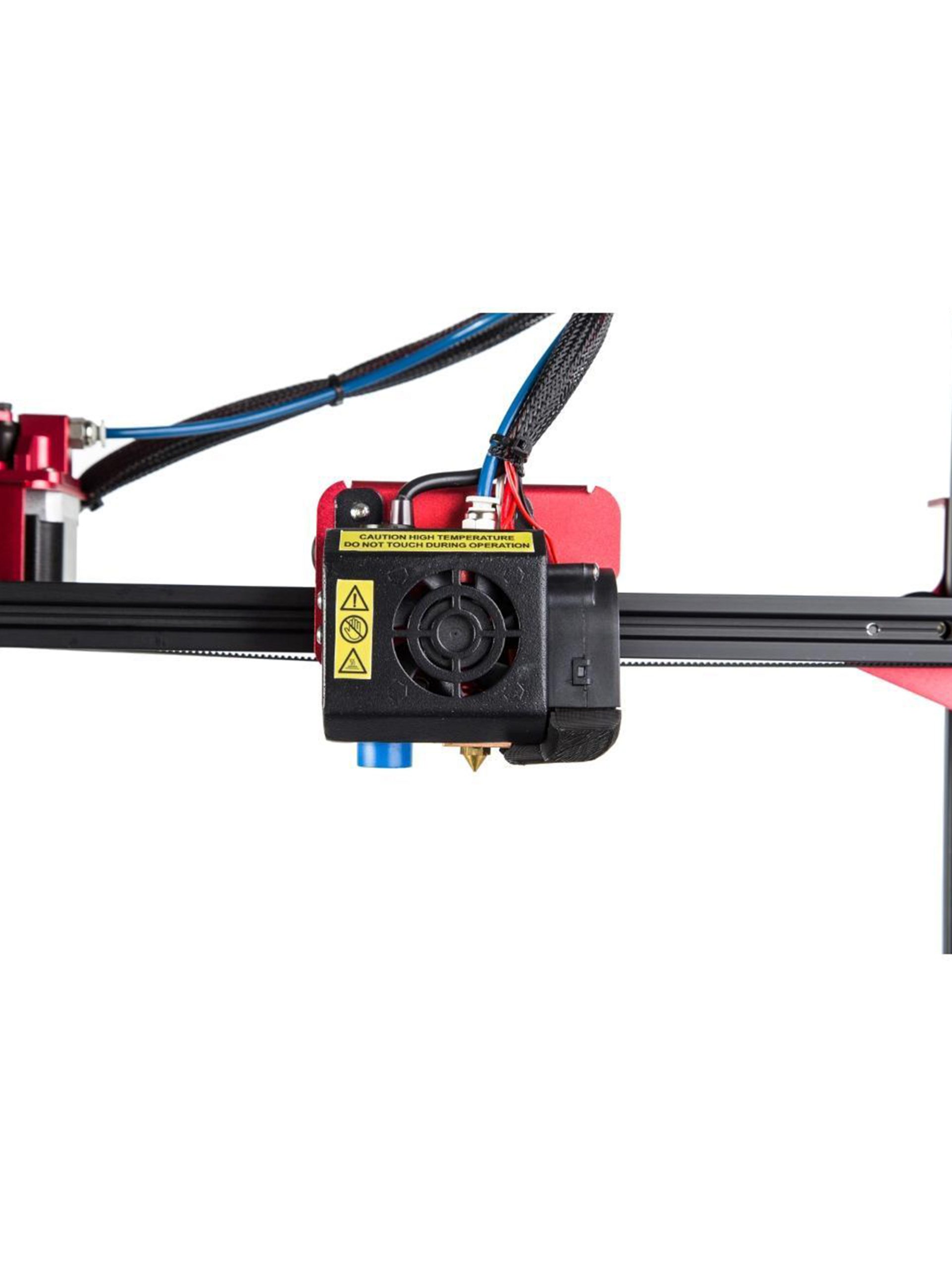

- Extruder type: Single nozzle

- Nozzle size: 0.4 mm

- Max. extruder temperature: 260 °C

- Max. heated bed temperature: 110 °C

- Max. print speed: 180 mm/s

- Closed print chamber: No

- Bed leveling: Automatic

- Print bed: Heated

- Display: LCD touchscreen

- Connectivity: SD card, USB

Features

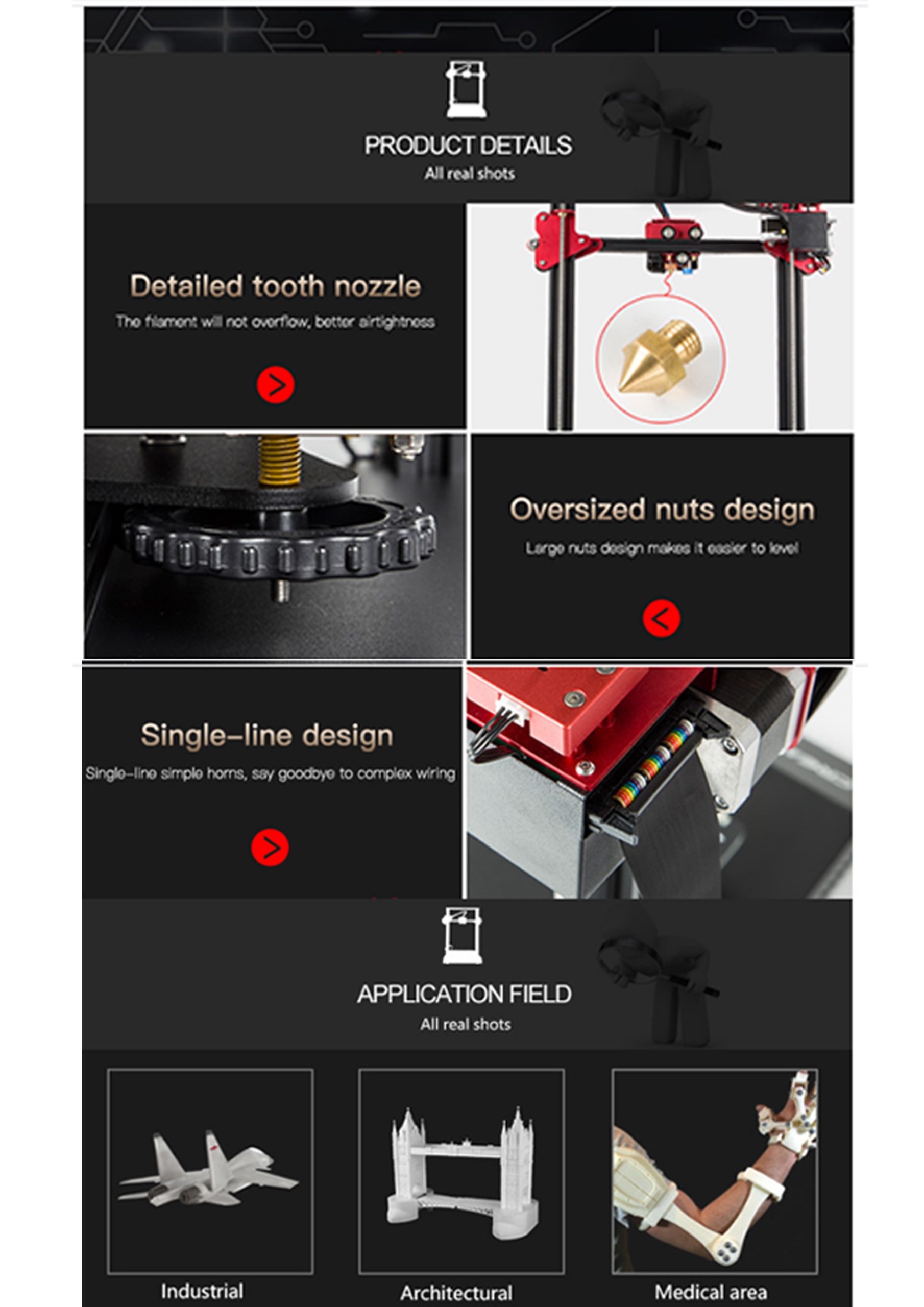

MATRIX AUTOMATIC LEVELING

It would appear that the CR-10S Pro features an inductive proximity sensor, gifting the printer the ability to automatically detect the bed and assist in reading a matrix of points across the bed for bed leveling. This much is standard and well known.

The company goes on further to hint at “Compensation sensor setting”, and “Auxillary leveling”. It is not clear, but we would presume this to mean a live Z-offset to help fine tune the bed level as you print.

V2.4.1 MOTHERBOARD

The Cr-10S Pro appears to feature an upgraded version of the mainboard used in the CR-10S. It is claimed to increase the stability and reliability of the printer’s performance, but in the absence of any metrics, there’s nothing we can say to this. It is hinted that the board has TMC drivers, but not explicitly stated which drivers are present. If so, this should sum up to a quieter printer that handles vertical planes and curves with fewer “salmon skin” artifacts.

IMPORTED TEFLON TUBE

Paying heed to the Bowden extruder arrangement on the CR-10S, the CR-10S pro boasts Capricorn Teflon tubing – possibly the best option for filament feeding in this way, due to high lubricity and high-temperature resistance.

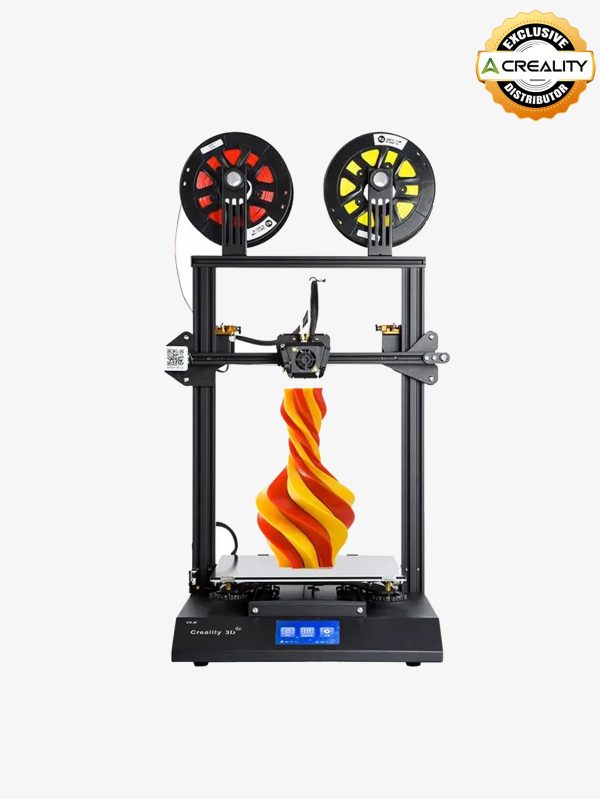

TOUCH SCREEN

Gone is the dot matrix LCD of the CR-10S, replaced by a vivid touchscreen unit and simplified UI. It very much looks to have been lifted from the CR-X. Indeed, the general arrangement of the base unit, with integrated power, mainboard and display appearing to be that of the CR-X.

Further similarities between the two come in a 300 x 300 x 400mm print volume, with a glass bed coated in an adhesive sticker.

RESUME PRINT FUNCTION

A welcome feature for those that take advantage of that large build volume comes in print resume functionality. The CR-10S Pro will be able to pick up printing from where it left off after a power cut.

The original CR-10S has an auto-resume function, so it’s business as usual here for the line.

FILAMENT DETECTION

As with the CR-10S that precedes it, the CR-10S Pro features filament runout detection – again a welcome feature on long filament guzzling prints.

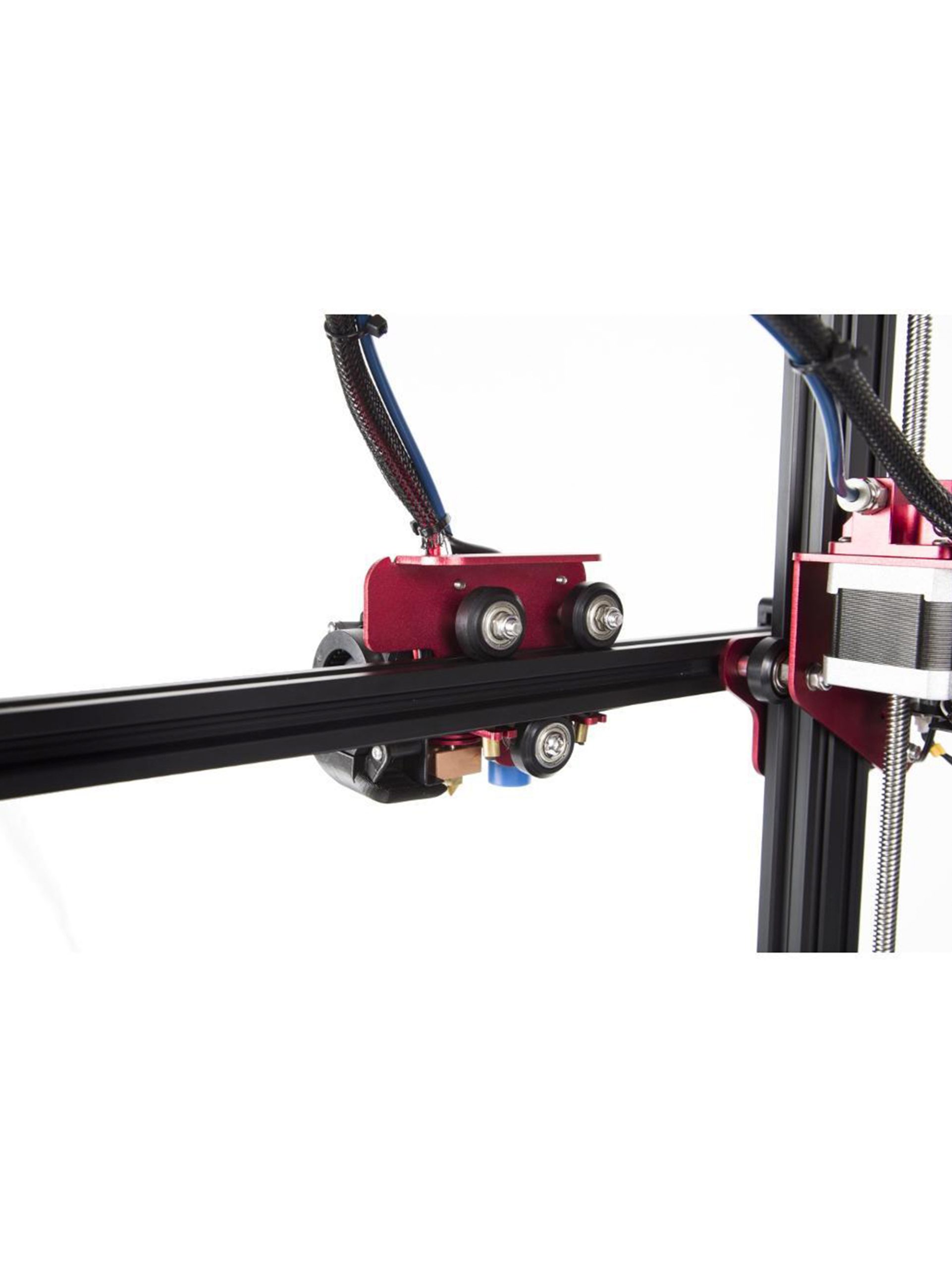

DOUBLE GEAR EXTRUSION MECHANISM

One of the more exciting hardware upgrades is the addition of a Bondtech-like dual gear feed in the extruder. Such a system should result in a more reliable and stronger feed of filament into that shiny new Cap’ tube. We likey.

QUICK HEATING PRINT BED

Creality claims the CR-10S Pro’s heated bed can heat up to its max temp of 110 degrees Celsius in 5 minutes. Looking over the spec sheet, the output rating of 24V should confirm this to be the case.

BRANDED POWER SUPPLY

The documentation for the CR-10S Pro shows a Mean Well power supply, a reputable brand that’s known for the reliability and safety of their PSUs.

Beyond these nine main features, the Creality CR-10S continues the design language of the brand’s recent printers — ribbon over aviation cables, oversized bed leveling nuts. From the CR-10S, we see a dual-leadscrew setup too, which should help with stability printing in the upper range of the build volume.

Reviews

There are no reviews yet.