3D Prototyping

What is Rapid Prototyping?

Rapid prototyping, also known as 3D prototyping, is not only limited to 3D printing. It refers to a process of iterating through a design by quickly manufacturing physical prototypes and making small changes at each step to improve it.

One of the most popular uses of 3D printing, which gives a great deal of versatility in terms of speed and material options, is rapid prototyping. Although the technique is not suited for mass production, 3D printing enables the fabrication of low- to medium-performance products at a low cost. When using 3D printing, materials are added until the desired shape is achieved, which is known as additive manufacturing.

Various types of 3D printing technologies are available depending on the amount of accuracy required:

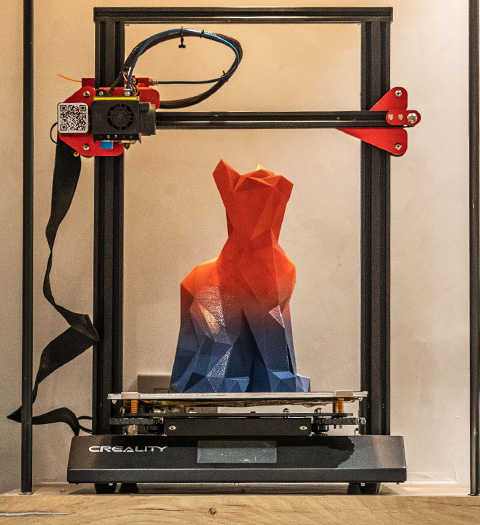

Fused deposition modeling (FDM):

The most well-liked and reasonably priced 3D Printers employ a thermoplastic filament that is melted and extruded layer by layer. It is advised to use them for initial prototypes or personal use.

SLS (selective laser sintering)

These 3D printers use powder that is sintered with the aid of a laser layer by layer until you get a solid model. Because it is a more specialized 3D printing technique, it is advised for high-end industrial prototypes.

SLS (selective laser sintering)

SLA 3D printers have tanks filled with liquid resin into which a platform gently descends and then rises as each layer is solidified by UV light. The procedure is continued until the 3D model is finished. SLA can produce parts with very high dimensional accuracy and with intricate details.

SLS (selective laser sintering)

WOL3D provides product development of new products from scratch. It involves a complete product development cycle from idea generation to the end of the product life cycle.

Architecture Model Making /

Miniature Scaled Models

We specialize in creating premium architectural scale models using the latest innovations in 3D printing and laser cutting technology.

3D Scanning / Reverse Engineering

WOL3D is a leading provider of 3D scanning services and product design. We specialize in on and off-site 3d laser scanning and CAD modelling services.

Vacuum Casting

Vacuum casting is a formative manufacturing process that provides low-volume parts with production-level quality.

It is an iteration technique used for producing samples or versions of functional plastic parts, through the use of silicone moulds. VC is a great method to make rigid or flexible parts and is ideal for high-quality prototypes, function testing, concept proofing, and display demos.